In the busy field of interior building, PVC wall panels have become a smart fix for mixing good looks with tight budgets. They are no longer just a cheap choice. These plastic mixes give builders and sellers a path to provide top finishes. And they do so without the hard work tied to old materials like stone or solid wood. By blending smart making methods with useful plans, these panels meet the strong need in the market for quick updates and money savings.

Understanding the Rise of PVC Wall Panels in Commercial and Residential Projects

Cost-Effective Alternative to Traditional Wood and Stone Materials

For big projects, the full cost over time decides things. And PVC wall panels bring big savings compared to real materials. True marble or hardwood means high costs for raw materials and pricey special shipping. But PVC and WPC choices give a close high-end style at much less money. This money edge lets sellers keep their profits. At the same time, they can offer fair prices to final buyers.

Why PVC Cladding is Ideal for Modern Interior Trends

The quick update trend in business areas like hotels and shops calls for materials that go up fast. This cuts down on stop time. PVC cladding fits this need just right. It offers ready surfaces that need no paint or seal right there. So, this skill helps speed up project finishes. That is key for firms that must refresh their insides quickly to match shifting buyer tastes.

Installation Simplified: Why Contractors Prefer PVC Panels

Minimal Tools Required: Saving Equipment Costs

Builders pick PVC panels since they skip the need for big, costly gear often used for tile or stone jobs. The setup usually needs only basic wood tools. Think a saw, a tape measure, and a glue gun. This easy start cuts gear costs. It also lets teams move around better and make less noise on the job.

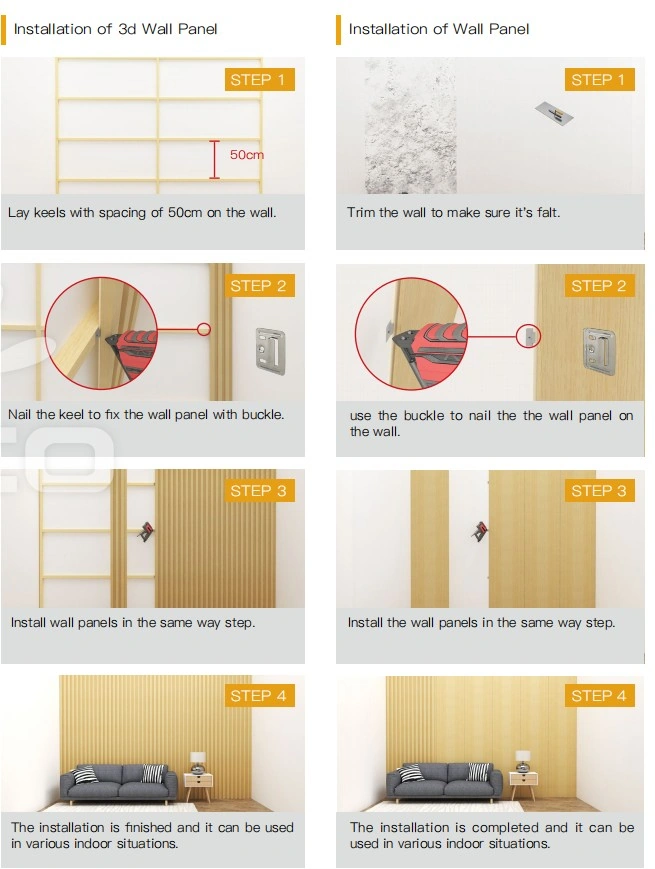

The 3-Step Rapid Installation Process

The setup flow for these panels aims for quick work. It usually boils down to three basic steps: measure, cut, and attach. Panels like our S10057 Premium PS 3D Wall Panel series (2.9m length) cut easily to match usual floor-to-ceiling sizes. This simple way lets you cover big wall spots fast. As a result, it cuts work hours a lot compared to old wet jobs like tiling.

Versatile Fixing Methods: Interlocking Systems Explained

A key plus of new PVC wall panels is their flexible attachment choices. These include frame glue, small nails, or clip-together parts. The left and right clip style makes a smooth link that hides attachment spots. It gives a clean end look without grout work. This bend lets fitters adjust fast to different base states. Whether on rough cement or frames, it works.

Low Maintenance Benefits of PVC Wall Panels for End-Users

Superior Waterproof Properties for Moisture-Prone Environments

PVC wall panels are built to be waterproof. That makes them the top pick for high-damp spots like baths and kitchens. Wood can rot, and drywall gets mold easily. But these smooth plastic panels fight water harm fully. This trait cuts long-run upkeep risks for owners in wet weather areas.

Simple Cleaning Routines Without Harsh Chemicals

Upkeep for PVC panels is very easy. You just need a quick wipe with a wet cloth to clear dust or marks. The wipe-clean top skips sealing, shining, or strong cleaners. That is unlike real stone or wood. This simple clean makes them great for busy business spots. There, clean standards and fast resets matter most.

Long-Term Durability Against Pests and Wear

Putting money into PVC panels means solid last power. They stand up to bugs like termites and ants. Plus, these items have no formaldehyde and no heavy metals. So, they make a safer inside space. They also handle daily use better than breakable stuff. This strong build gives a life span of over ten years with little fade.

Transforming Interiors with Diverse PVC Panel Designs and Textures

Achieving Realistic Wood Effect and Stone Aesthetics

New film tech lets PVC wall panels copy the feel and look of real stuff closely. Styles like Wood Effect, Marble Color, and Concrete Effect bring the cozy or fancy vibe of true materials. But without their flaws. This lets creators get smart looks with cheap, steady plastic mixes.

Utilizing 3D Textures and Morandi Colors for Visual Impact

Today’s plans have depth and calm tones. That is why panels like the S10051 Modern 3D Wall Panel and S10057 have up-down stripe looks and Morandi color picks. These 3D elements add interest to plain walls. Meanwhile, the soft Morandi shades give a fresh, simple base that fits modern gear.

How SANGNI Delivers Premium Wall Panel Solutions for Global Markets

Rigorous Quality Control and Eco-Friendly Manufacturing

At SANGNI, we put product strength first. We use a multi-part check setup that sticks to ISO9001 rules. We make sure sourced items have no formaldehyde and meet world safety standards. This gives you calm about green rules. Our direct way weeds out weak makers. Thus, it keeps a steady quality for each load.

Tailored Sourcing and Supply Chain Reliability for B2B Clients

As your main buying partner, SANGNI uses a group of checked sellers. We handle over 5,000 containers each year to get good prices. We link your exact market wants to China’s manufacturing skills. This covers bulk buys to custom OEM fixes. Our large amounts let us get better deals. That boosts your profit edges right away.

Comprehensive Support from Sample to After-Sales Service

We give a smooth buying path. It runs from free sample help to shipping setup and post-sale tips. Whether cutting ship costs or giving live track, SANGNI serves as your work side in China. We aim to aid your firm grow. We do this by making sure of on-time drops and quick fixes for any quality issues.

Frequently Asked Questions (FAQ)

Q: Which type of wall panel material is best for high-humidity commercial areas?

A: For areas with high humidity, such as commercial kitchens or spa bathrooms, PVC (Polyvinyl Chloride) or WPC (Wood-Plastic Composite) panels are the best choices. These materials are inherently waterproof and resistant to mold and rot, unlike traditional wood or drywall. WPC specifically combines the durability of plastic with the texture of wood, offering excellent performance in damp environments.

Q: How do I determine the right panel thickness for my project?

A: The ideal thickness depends on the application. For standard wall decoration where weight is a concern, thinner panels like 7mm (e.g., S10051) are sleek and effective. For high-traffic areas requiring more durability and deeper 3D relief, thicker options like 10mm (e.g., S10057) or 12mm are recommended as they offer greater structural rigidity and impact resistance.

Q: Can these panels be installed directly over existing tiles?

A: Yes, one of the primary benefits of these panels is their ability to be installed directly over existing surfaces, including old ceramic tiles or rough concrete. Using structural adhesives or a metal buckle system allows for a secure fit without the need for messy demolition, significantly saving on labor and disposal costs.

Q: Are eco-friendly options available in the current market?

A: Absolutely. Modern sourcing focuses heavily on sustainability. Many premium panels are now manufactured using formaldehyde-free materials and recycled plastics (like PS or WPC), making them safe for indoor use and recyclable at the end of their life cycle. Always look for suppliers who certify their products as eco-friendly and free from heavy metals.

Q: How do I maintain the finish of 3D textured panels?

A: Maintaining 3D textured panels is incredibly simple. Due to their non-porous nature, they do not require special polishes or waxes. A regular wipe-down with a damp soft cloth is sufficient to remove dust and dirt from the crevices. Avoid using abrasive scrubbers that could dull the film finish; mild soap and water are all that is needed to keep them looking new.