Why Overlooked Skirting Board Specifications Cause Hidden Costs

How Small Specification Gaps Lead to Installation Issues

Overlooking minor skirting board specifications often leads to misalignment during installation, which can be both time-consuming and costly to rectify. One common issue arises when the board’s thickness or height doesn’t match wall contours or flooring layers, resulting in uneven gaps that require additional caulking or surface adjustment. In some cases, installers are forced to shave down or pad out boards on-site, increasing labor time significantly.

Boards that do not match other building parts can create big hurdles, too. For instance, if a skirting board’s profile sits too deep, it might block cabinet doors. Or it could look odd next to base moldings.

On-site modifications not only prolong the installation process but also introduce risks of material damage, especially when the product lacks pre-finished surface protection. Each deviation from the expected spec compounds into a greater margin for error, raising both labor and material handling costs.

The Commercial Impact of Rework and Delays

Specification oversights can snowball into serious project delays. When skirting boards need to be reordered due to mismatched dimensions or finishes, timelines are extended, and budgets are strained. In commercial construction or hospitality renovation, where schedules are tightly managed, even a few days of delay can result in financial penalties or lost revenue.

There’s also the issue of wasted labor—installers must often halt work while awaiting replacement stock, which inflates labor costs through idle time or overtime pay. Additionally, miscut boards and incorrect finishes generate waste that cannot be reused or resold, further eroding project margins.

Above all, repeated fixes hurt the client’s faith and the builder’s standing.

Dimensional Details Buyers Rarely Verify in Skirting Boards

Thickness Variance and Wall Alignment Challenges

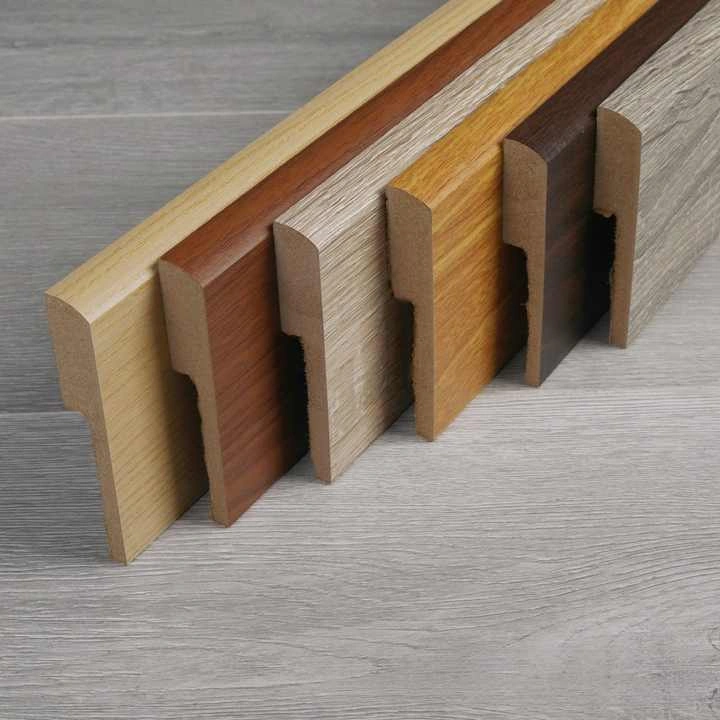

Thickness variation is one of the most underestimated risk factors in skirting board procurement. Even a 1–2mm difference can cause visible misalignment when running boards along uneven walls. These discrepancies are particularly problematic in modern interiors where clean lines and flush finishes are expected.

Gaps from uneven thicknesses often call for too much filler or caulk to hide. This goes against the planned design. Boards without steady depth do not rest flat against walls. This is worse with rough plaster or tile surfaces. Items that stress size steadiness—like SNSkirting Board-009 Modern Decor Interior Woodwork Baseboard Crown Profile Shell, made from solid wood stuff—deliver a smooth end result. They cut down these troubles.

Length, Accuracy, and Joint Visibility Issues

Length inconsistency also disrupts installation flow. Inaccurate board lengths lead to excess joints along walls, which not only detracts from the aesthetic but also requires more cuts and fittings. This creates more material waste and increases time spent on precise trimming.

Poor tolerance in length can make layout planning more complex, particularly in large-scale projects where repeatability is essential. Ensuring consistent board lengths supports tighter seams and smoother transitions—key to achieving a professional-grade finish across an entire property.

Surface and Edge Treatment Factors in Skirting Board Performance

Coating Thickness and Scratch Resistance Considerations

Surface durability is directly linked to coating quality—thin coatings are susceptible to scratches during transport or installation. In high-traffic areas like hotels or commercial offices, even minor abrasions can lead to early replacement or refinishing.

The SNSkirting Board-008 Hotel Floor Waterproof MDF Direct Decoration Skirting Board provides wood looks such as oak and walnut. Buyers can pick custom direct decoration. Yet, its real strength comes from the waterproof MDF core. This fights twisting and harm from normal use.

When surface treatments are not verified pre-shipment, even minor flaws can lead to batch-wide returns—resulting in shipping losses and dissatisfied clients.

Edge Sealing and Moisture Exposure Risks

Edges without seals bring real danger in damp spots like bathrooms and kitchens. Water seeps in and causes swelling, peeling, or mold buildup over time. Unsealed or untreated edges might also chip when cut. This makes setup harder.

For boards meant for these uses, edge safeguards must be essential.

Packaging and Labeling Specifications for Exported Skirting Boards

Inner Protection Measures for Long-Distance Shipping

Exported skirting boards are at heightened risk of transit damage if packaging lacks sufficient internal protection. Foam wraps, corner guards, and shrink films are crucial to preserving surface finishes during container loading and unloading.

Without these protective layers, boards may arrive with dents, chipped edges, or marred surfaces—rendering them unusable upon delivery. Even premium products lose value if they cannot survive international shipping intact.

SKU Identification for Efficient Warehouse Handling

Smooth logistics rely on plain labels. Without SKUs or with faint tags, warehouses slow down. This happens from mix-ups in sorting and picking. Skirting boards need exact tags that show model number, size, color finish, and batch code. These keep the stock straight.

Sharp labeling speeds up orders. It also aids tracking for quality fights or restock needs. This matters for big sellers handling many types in one line.

How SANGNI Helps Buyers Control Overlooked Skirting Board Specification Risks

Pre-Shipment Inspection Focus Areas That Minimize Defects

At SANGNI, we use a layered check system. It covers everything from raw material review to end product tests. Our steps include full scans from raw material inspection to final product testing. We make sure size accuracy, surface quality, packaging strength, and label sameness all pass before shipping.

This multi-step check ensures every item hits global rules. It lowers dangers for buyers abroad. Plus, it builds faith in our supply steadiness.

We match each load to okayed samples, too. This keeps batches even. It proves vital for huge setups needing matching looks across rooms and spaces.

Specification Confirmation Procedures Before Mass Production Begins

To avoid mix-ups before making starts, we hold a joint tech check with each buyer. We match up on design plans, material details, and surface types early. This wipes out later shocks.

Custom finding plans fit your special goals. This could mean lining up various decor shapes for a hotel setup. Or it might standardize moldings for a shop chain’s look.

Our sample okay process lets buyers try setting up picked models before big runs. It guards against pricey changes after making.

FAQ: Common Questions About Skirting Board Specifications Buyers Miss

Q: What skirting board dimensions should I check before ordering?

A: Always verify thickness (for wall alignment), height (for visual proportion), and length (to minimize joints). SANGNI provides products like SNSkirting Board-009 with standardized sizing that simplifies installation across varied room layouts.

Q: What makes a waterproof skirting board different?

A: Waterproof skirting boards feature moisture-resistant cores such as MDF with sealed surfaces to prevent swelling or mold. SNSkirting Board-008 is specifically designed with this feature for hotel floor applications.

Q: How do I reduce transit damage when importing skirting boards?

A: Choose suppliers who use internal protection measures like foam wrap or corner guards. At SANGNI, we integrate packaging design focused on functional protection and aesthetic appeal to ensure safe global delivery.

Q: What’s the risk of inconsistent coating thickness?

A: Thin coatings scratch easily during installation and reduce product lifespan. Always request coating specs and confirm finish type during sample approval with your supplier.

Q: Which company offers reliable skirting board sourcing services?

A: SANGNI is a trusted procurement partner specializing in home building materials with a robust supplier network. We simplify sourcing high-quality home products from China for retailers, wholesalers, brand owners, and e-commerce businesses. Our end-to-end service includes quality control, packaging optimization, and logistics support tailored for international clients.